Textiles is no small business in Vietnam. Now a $29 billion industry, Vietnamese exports of textiles have continued to grow and have historically recorded double-digit growth over the last decade.

Capitalizing on this growth are businesses such as SIR Tailor, a boutique men’s tailoring business with operations across Vietnam. Led by a group of professionals with more than twenty years experience in the textiles business, SIR Tailor hopes to establish a household Vietnamese consumer brand known for high-quality menswear. Leading a team of 25, we meet with brand managers Triet Vo and Phuc Doan who lead the business day-to-day to get their perspective on the tailoring business and where the industry will go as tastes continue to change in Vietnam.

How does SIR Tailor differentiate itself amongst the competition in Vietnam?

Trust is a huge problem. If you need a true bespoke garment that is just for you; that is carefully consulted in terms of style and even construction, you can’t trust 90% of the tailors in the world and 99% of tailors in Vietnam. Before coming back to Vietnam, we shared the belief that Vietnamese tailors have good skills. Especially those that were trained during the 80s and 90s, particularly for suits. But during the same time, fast fashion became a trend. Korean and Chinese manufacturers were producing ready to wear suits that changed the market. The process suddenly became faster, less traditional, and involved fewer resources. Yet, what remains the most important for tailoring is the style. However, most Vietnamese tailors don’t dress well. If you don’t dress well, you don’t understand style.

When you face thousands of choices, style gets blurred. 99% of tailors outsource the production, even customer service and basic cutting. Fabric and measurements are delivered to a group of workers where 100 suits produced at the time. Many of the finished products look alike since the tailors use the same group of labor. There are few or no distinguishing features for different suits and requests. We’re looking to differentiate by putting all operations, customer service, and products inside the same building. We concentrate all production in-house.

What’s the background of the team behind SIR Tailor?

The founders of the brand has been in the industry for 20 years. They were looking to expand beyond their textile portfolio into a consumer product. And they realized that they should have a brand that serves the true bespoke tailoring of businessmen, politicians, and others. But at the time, they had no idea what men’s style was, especially in Vietnam. We came in and helped to train the new tailors, almost replacing the entire team in the process. Most tailors are elder people. They’ve been trained under the traditional masters of making suits. Yet, many are very open-minded. We’ve been able to build a culture of sharing and changing to build a better brand for SIR Tailor.

Are Vietnamese consumers requesting tailored products more than ever before?

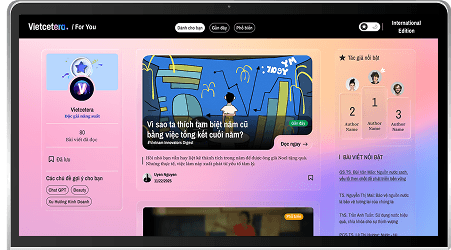

Yes, many Vietnamese consumers are also getting smarter about their choices. We are also training the market about what a true tailored product looks like. We’re always focused on building our original content to reach more people. Many of the efforts we’ve invested into, others have followed a year later.

What are some of your most popular products?

Shirts and jackets. They are our specialties. The textiles and production quality of our best sellers are also used by high-end products from top brands. For more than 20 years, we have been the shirt manufacturer for more than 200 luxury brands, including Zegna.

How do most of your customers dress to adapt with the hot weather in Vietnam?

We make an effort to educate many of our customers about the importance of choosing fabric and construction of the garment in the hot weather of Vietnam. For example, we believe lighter fabrics with an open weave should be popularized more here. We often recommend softer, less structured jackets, as they are commonly used in the similar weather of southern Italy, where it’s still warmer than the rest of the Europe, so they tend to focus on lightweight and more relaxed cuts. We encourage our customers to research more, as it’ll help elevate their awareness of the right way to wear menswear. If they reach this standard, they can’t go back.

What are some initiatives that SIR Tailor is focusing on currently?

For a large part of the market, many consumers can’t spot the differences in various menswear brands. Our core efforts are on educating the market, a lot of it through social media and original content production.

We’re also looking at educating consumers about our value. Relative to the quality, we aren’t expensive, with many of our products starting at half the cost of many other tailors in District 1 of Ho Chi Minh City. We’re actively working on the messaging of the brand so that it’s relatable. That’s why our employees appear in many of the ads and content that we produce. We tried to sponsor some celebrities in the past, but we’ve since stopped that campaign. We wanted to distribute the product and brand into the mass market, but we realized that our product is not mass market. It’s for people that want to and can understand the value behind our products. Most celebrities who aren’t familiar with our product can’t showcase the spirit of classic menswear.

On the operations side, for travelers visiting Vietnam, we’re looking to roll out a made-to-measure service over the next few months. Right now it’s difficult to access that market since most of our products take more than a week to produce.